|

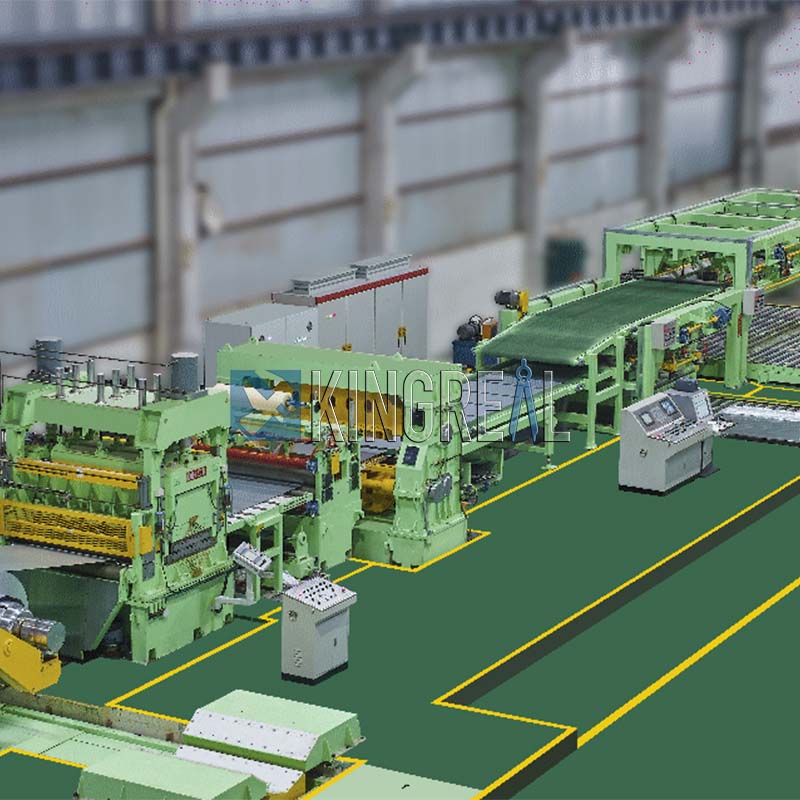

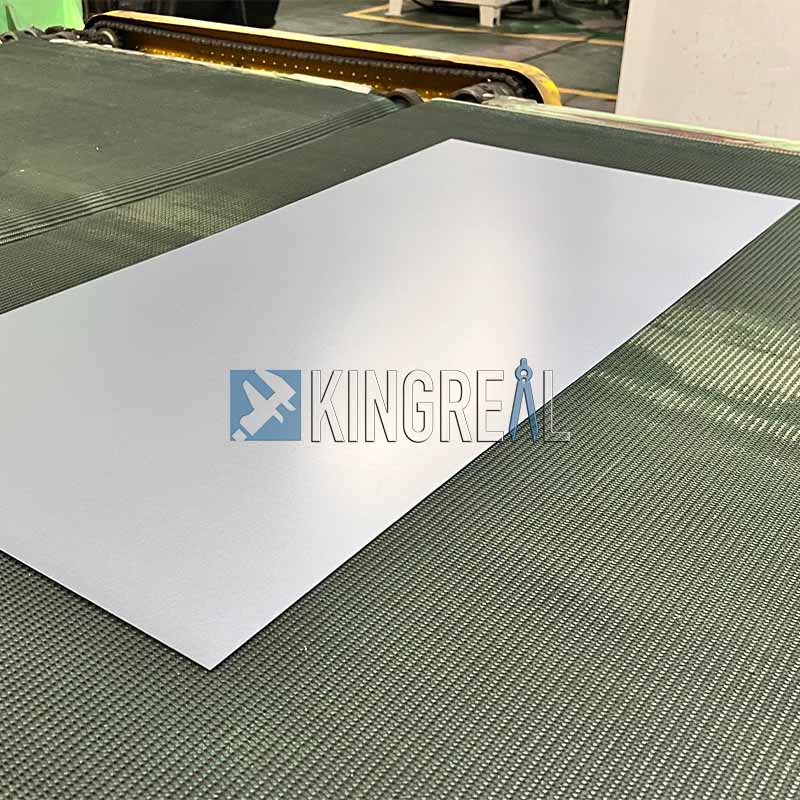

The fly shearing cut to length line is BRUTE STEEL SLITTER featured machine. In terms of high-precision and high speed cut to length line technology, BRUTE STEEL SLITTER is not only proficient in thin plates, rotary shears, flying shear fly shearing cut to length machines, but also in heavy duty and medium duty cut to length lines. So far, the fly shearing cut to length machine project has been successfully operated in the United States, Singapore, Malaysia, Russia, Sweden, Greece and other countries. At the same time, BRUTE STEEL SLITTER engineers have also traveled to customer factories in these countries to install the fly shearing cut to length line for them and train them on the correct operation of the fly shearing cut to length machine. BRUTE STEEL SLITTER specific fly shearing cut to length line projects are as follows: 1. The fly shearing cut to length machine can be equipped with a double leveler to ensure the excellent flatness of the metal sheet. 2. The fly shearing cut to length line is equipped with a laminating device to ensure that there are no scratches on the surface of the metal sheet. 3. The fly shearing cut to length machine uses hydraulic cutting and servo length tracking to ensure accurate cutting length. 4. The fly shearing cut to length line can be equipped with an automatic stacking system to automatically stack the plates and liberate manpower. |

|

If you have special requirements for the fly shearing cut to length machine, or need to add certain parts to the fly shearing cut to length line, please come to consult BRUTE STEEL SLITTER. BRUTE STEEL SLITTER strives to meet customer requirements, truly solve problems for customers, and provide customers with fly shearing cut to length machines that truly meet actual production needs.

BRUTE STEEL SLITTER has an experienced technical team and advanced testing equipment, focusing on the customization and maintenance services of fly shearing cut to length lines. BRUTE STEEL SLITTER knows the importance of each fly shearing cut to length machine to you, so BRUTE STEEL SLITTER will provide you with professional solutions with the most rigorous attitude and the most efficient service.

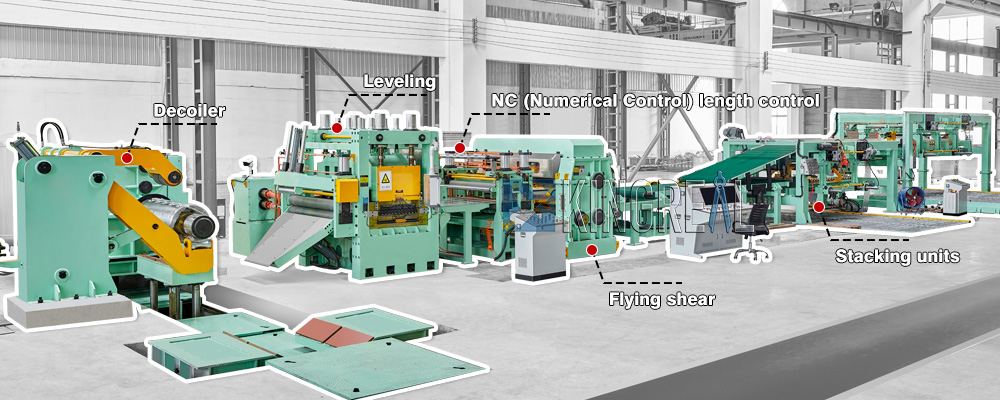

Fly shearing cut to length machine usually consists of decoiler, pinch roller and straightening device, leveling device, length measuring device, flying shear, and stacking device. It can be used for fly shearing cut to length lines for processing different metal materials such as thin plates, medium plates and thick plates. The fly shearing cut to length machine can accelerate the flying shear and synchronize it with the speed of the strip, and cut the material without stopping the feeding. This enables the flying shear to process a full roll of strip without accumulating the downtime required for the shearing cycle. Moreover, the maximum production speed of the fly shearing cut to length line can reach 80m/min.

The most important cutting link in the fly shearing cut to length machine involves a hydraulic shear that moves synchronously with the moving coil being fed. This hydraulic shear is called a flying shear and its forward and backward movement is controlled by a servo system. In one cut, the transverse shear is accelerated to the same speed as the moving coil to cut. After the cut is completed, the transverse shear returns to the initial position. In continuous cutting, these actions will be performed in a cycle. This technology can cut materials efficiently and quickly without pausing the production process.

|

Model |

Processing Thickness(mm) |

Processing Width(mm) |

Cutting Accuracy(mm) |

Max. Speed

m/min |

Max. Cutting (times/min) |

Uncoiling Weight(ton) |

|

Model 1 |

0.2-2 |

100-650 |

±0.3 |

80 |

150 | 5 |

|

Model 2 |

0.2-2 | 100-800 |

±0.3 |

80 |

150 |

8 |

|

Model 3 |

0.3-2 | 400-1300 |

±0.3 |

80 |

150 |

15 |

|

Model 4 |

0.3-2 | 400-1600 |

±0.3 |

80 |

150 |

20 |

|

Model 5 |

0.3-3 | 100-800 |

±0.3 |

70 |

150 |

8 |

|

Model 6 |

0.3-3 | 400-1300 |

±0.3 |

70 |

150 |

15 |

For any BRUTE STEEL SLITTER fly shearing cut to length machine, we offer a variety of options to increase the productivity of your equipment. Some of the options BRUTE STEEL SLITTER offers to maximize the capacity of your fly shearing cut to length line include:

● Coil handling equipment

● Regenerative braking to build strip tension

● Heavy gauge flattening machine

● Edge control to maintain consistent strip position

BRUTE STEEL SLITTER fly shearing cut to length machines use high-resolution feedback devices to provide tight cutting tolerances on any length of workpiece. BRUTE STEEL SLITTER most accurate fly shearing cut to length lines are available to achieve ASTM standard 1/8 cut lengths.

|

|

|

BRUTE STEEL SLITTER fly shearing cut to length lines have been used in a wide variety of applications. They have been applied in different industries and are equipped with the following options:

|

PLATE MATERIAL |

INDUSTRIES SERVED |

|

Steel Stainless Steel Aluminum Copper/Brass ...... |

Integrated Mills Mini Mills Aerospace/Military Manufacturing Service Centers Construction |

BRUTE STEEL SLITTER is an experienced expert in metal cut to length machine manufacturing. In addition to fly shearing cut to length machines, BRUTE STEEL SLITTER can provide other types of metal cut to length machines such as rotary shearing cut to length lines, swing shearing cut to length lines, fixed shearing cut to length lines, simple cut to length lines, light duty cut to length lines, medium duty cut to length lines, heavy duty cut to length lines and other metal cut to length line manufacturing solutions. If you are interested in fly shearing cut to length machines or have any questions, please come to consult BRUTE STEEL SLITTER! BRUTE STEEL SLITTER staff will definitely give you a satisfactory fly shearing cut to length machine manufacturing solution based on your drawings after fully understanding your production needs!